Polymer Clay Molds That are Awesome

Polymer Clay Push molds are very easy using FIMO or Sculpey, Polymer Metal Clay (PMC), Plasticine clays, and other clays. You can even use the Formable Plastics.The ComposiMold and ImPRESSive Putty give you the ability to make, and re-make the clay molds using an original shape that you then re-cast in molds by taking the original to be molded and also to make the castings.

We recommend theImPRESSive Putty or theComposiMold-Firm for firm clays To use, just press the polymer clay into your molds and pull the clay out. Do not bake the polymer clay in the molds.

Using ImPRESSive Putty for Clay Molds

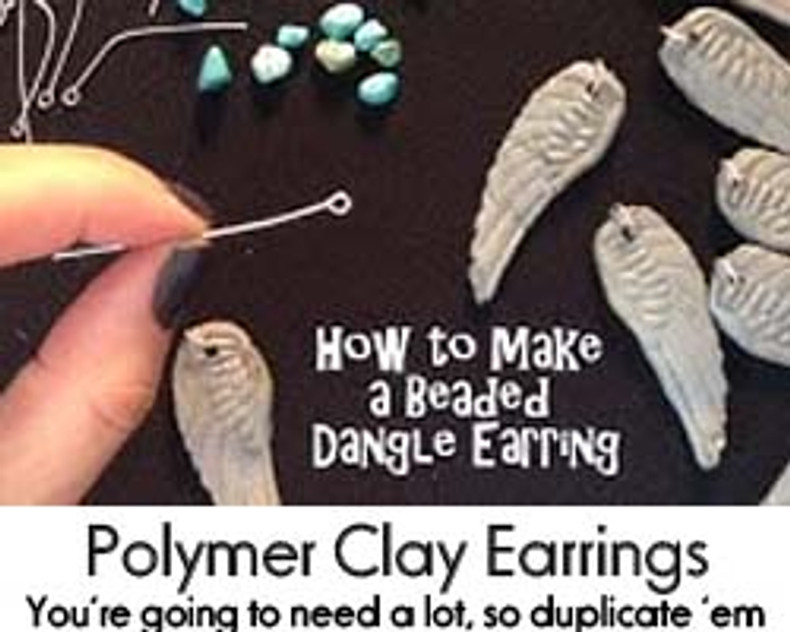

Clay Push molds are a simple and effective way of making 3-D objects super fast and easy. For example, buttons can be pushed into a mold in seconds flat using most types of polymer clays or doughy casting materials. It's a great way to make polymer clay charms for jewelry.

ImPRESSive Putty is a great way of using natural objects or making a large number of castings quickly. Soften the ImPRESSive Putty in the microwave. A 6 oz. size of ImPRESSive Putty softens in about 40 seconds in most microwaves.

The video below shows the re-melting of the ImPRESSive Putty from the leaf to make a candle and candle holder. This is a two part mold for polymer clay.

To Mold Clay in a ComposiMold Mold:

Mold clay and polymer clay by using ComposiMold. Air dry clay and other modeling clays make excellent and simple casting materials to mold clay into the shapes you want. You can learn how to make clay molds with ComposiMold quickly and easily. Use an existing found object to create a clay mold or even sculpt your own master object and then make a mold out of it. You'll be creating duplicates of your sculpture in no time!

Follow the basic instructions on our How To Use ComposiMold Page to make a mold with ComposiMold. The tips below will set you up for success when creating a great push mold for polymer clay, FIMO, Sculpey, play dough, PaperClay, and even fondant or gum paste for edible shapes.

The Keys to Making Clay Push Molds in a ComposiMold Mold:

Think of a push mold as a negative space for you to press your casting material into to pick up the details of the original shape.

1. Soften your modeling clay or air dry clay per product instructions. Often this means working it in your hands until it has warmed slightly and becomes doughy in texture.

2. Apply Mold Release if you find that it helped your modeling clay release from the mold.

3. Press your clay casting material into your mold. Be sure to press the clay into the lowest points of the negative space first. This will ensure that the clay casting material picks up all the details of the mold.

4. Carefully remove your clay casting from the mold. This can be done by turning your mold upside down and letting it fall out. (You may have to slightly bend your mold away from the clay to release it.)

5. If your modeling clay distorts when you pull it out of the mold, refrigerate the mold and clay. This will make the clay harder and firmer allowing you to pull it out of the mold more effectively with less distortion.

Enjoy.