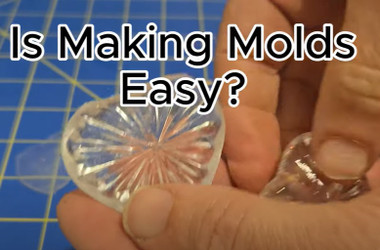

Is Making a Mold This Easy?

Posted by ComposiMold on 20th Jun 2025

You might not believe how simple mold making can be, until you try it yourself.

Today, we’re making a mold of this beautiful clear glass heart using ComposiMold, our reusable mold making mater

… read more