Mold making is a process that you use to duplicate other objects, but mold making will take some experimenting. The reason ComposiMold exists is because I used to make a lot of mistakes and I was frustrated at wasting my money on molding materials that I'd only use once.

A RESIN can be epoxy resin, urethane resin polyurethane resin, acrylic resin, polyester resin, or vinyl resin.

The mold making process is simple, but there are many different ways to duplicate something. So you are in a good place to start with ComposiMold. Have you checked out our ebook? Free E-Book

Start with that and some of the videos...one you might like is http://composimoldstore.com/projects/#owllighthanger.

I also recommend starting simple. A shape that is flat on one side. A relief sculpture.

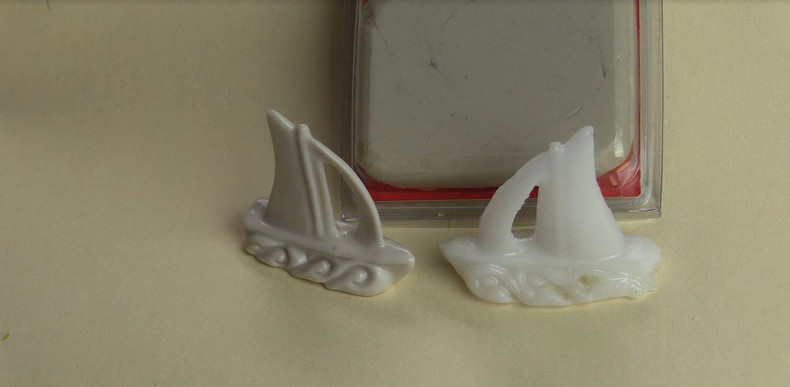

Another option is to use the ImPRESSive Putty. It makes the mold making process very simple and much easier to conceptualize. The Putty is heated and you press it over your part. After it cools to solidify, you have your mold and you pour or press in your casting material. Because it’s so straight forward, this is a great material to learn mold making. We have been using it for children down to about 8 years old (with adult supervision because the Molding Putty can be hot out of the microwave until it cools).

Mold making is the process used to duplicate three dimensional models or objects. A model is any object that has depth, and an original model can be made from almost anything. If you were making your own object to mold, you might use clay, rock, or plastic. Through the use of a mold making material a negative, or a reverse, of a model part is made, the negative can then be used to cast a second part that is the same size and shape as the original part.

Simple parts such as relief sculptures can be duplicated by using a one part mold. The casting material is poured or pressed into the mold indentation. The casting material can range from clay, soap, chocolate, concrete, liquid plastic, play-dough, and metal castings.

You can make two part molds or even three or more part molds. Mold sizes can range from a few millimeters to many feet in size. Mold making is used in industry to make duplicates of a wide variety of creations ranging from car parts to Christmas ornaments. More complicated molds may include a variety of molded parts, rigid parts of the molds, inserts, a variety of resins and fillers, and a lot of setup and thought.

At home mold making is typically performed using a rubber mold making material that can be poured on or around the object to be duplicated. The mold can then be filled with casting materials of your choice. For example, many cake decorators or chocolate makers use molds to create unique shapes from their chocolates or use molds to shape fondant into special shapes. Home soap and candle makers duplicate unique shapes and designs. Hobbyist use molds to make components for their trains and to make improvements to the backdrops and sceneries. Even fishermen enjoy molding their own unique fishing lure

Mold making can be fun and useful. With patience and persistence, you can mold and cast just about anything. You can make unique gifts and fix broken parts. To learn more about molding, casting and the products associated with Mold Making visit http://composimold.com.

| So why use a reusable mold making material? Re-usable Mold Making provides many benefits to you as the maker, the artist, the hobbyist, the gamer, the crafter: 1. Stop spending money on molds, and start making. 2. Enables you to create dozens and dozens of new molds anytime you want.3. Great shelf life, so it's there when you want it. 4. Use what you want for big molds, little molds, simple molds, and complex molds. 5. Eco-friendly and safe for you to use. 6. Super easy to use: no mixing or weighing or using too much. |

Mold Releases:

For the mold making with ComposiMold, we have a mold release available, but you can just use vegetable oil or mineral oil…or waxes…or silicone sprays… You may like spraying a little with Bubble Buster to reduce bubbles from sticking to your part. Spray this on after you add the mold release.

Urethanes: I recommend a barrier made with talcum powder (baby powder) because some polyurethanes are sensitive to the moisture in ComposiMold.

For epoxies: I usually stick with the vegetable oil or mineral oil…a very thin coating, and then I wipe it off.

|