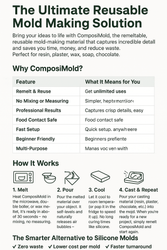

ComposiMold. The Ultimate Reusable Mold Making Solution and Silicone Replacement

Posted by ComposiMold on 10th Sep 2025

Bring your ideas to life with ComposiMold, the remeltable, reusable mold-making material that captures incredible detail and saves you time, money, and reduces waste. Perfect for resin, plaster, wax,

… read more